Chlorine Dioxide vs. Bleach in Water Treatment – Scientific & Industrial Guide

Walk into any treatment plant control room and you’ll hear the same refrain: “Safe water isn’t negotiable.” From municipal utilities supplying millions of gallons per day to private wells tucked behind rural homes, the stakes are identical—water free of pathogenic risk, harmful by-products, and off-flavors.

Yet chlorine dioxide (ClO₂) still prompts the inevitable question: “Isn’t that just bleach?”

The chemistry—and decades of industrial data—say otherwise. This article hopefully demystifies ClO₂ for water professionals, explains the disinfection pathway, contrasts it with sodium hypochlorite, and explores when a homeowner might legitimately look beyond simple filtration.

For decades, sodium hypochlorite—household bleach—was the default answer to microbial control in municipal and industrial water. It was inexpensive, familiar, and good enough for the regulatory standards of its time. But “good enough” is a dangerous comfort in an era of stricter discharge limits, higher uptime expectations, and infrastructure lifespans measured in decades.

Plant operators across the U.S. are now asking harder questions: Are we doing more harm than good to our pipes? Are we leaving compliance gaps with our current chemistry? Around those questions, a quiet revolution has been building. Chlorine dioxide (ClO₂), once considered exotic, is fast becoming the benchmark for serious water professionals.

1. Why This Comparison Matters

Clean, microbially safe water is the heartbeat of municipalities, food processors, cooling towers, and commercial buildings. For decades, sodium hypochlorite (NaOCl – “bleach”) has been the go-to oxidant, yet its pH sensitivity, corrosiveness, and carcinogenic by-products are driving operators to search for a better way. Enter chlorine dioxide (ClO₂), a selective oxidant lauded by regulators, utilities, and innovators like Scotmas, FILTEC, and ProMinent for its broad-spectrum kill, low by-product profile, and biofilm-busting prowess.

2. Chemistry at a Glance

| Property | Chlorine Dioxide (ClO₂) | Sodium Hypochlorite (NaOCl) |

|---|---|---|

| Oxidation Mechanism | Selective, single-electron transfer | Non-selective, forms HOCl |

| Effective pH Range | 4–10 (broad) | Narrow, best 6–7 |

| By-Products | Minimal chlorinated organics | THMs, HAAs, chloramines |

| Volatility | Gas, generated on-site | Liquid, decays in storage |

| Odor/Taste | Clean, neutral | “Chlorinous,” medicinal |

ClO₂ is a neutral free radical. It attacks cell walls via one-electron oxidation, sparing many organic molecules yet obliterating microbial enzymes. Bleach produces hypochlorous acid, a blunt multi-electron oxidant that reacts indiscriminately, raising by-product risk.

3. What Each Kills – and How Fast

| Microbe / Challenge | Chlorine Dioxide (ClO₂) | Sodium Hypochlorite (Bleach) |

|---|---|---|

| Gram-negative bacteria | Pseudomonas, E. coli, Legionella – rapid 4-6 log kill | Effective but slower at high pH |

| Gram-positive bacteria | Staphylococcus, Listeria – high susceptibility | Good kill, but inhibited by organics |

| Protozoa / Cysts | Giardia, Cryptosporidium – inactivation documented (AWWA) | Poor Cryptosporidium control |

| Viruses | Enteric, rotavirus, norovirus – high log reductions | Broad activity, slower at pH >7.5 |

| Biofilms | Penetrates EPS matrix, dismantles colonies | Surface kill only, penetration poor |

| Sulfide / Iron / Mn slime | Oxidizes & strips films, reduces staining | Partial oxidation, precipitates form |

| Taste & Odor | Neutralizes phenols, sulfides, algae compounds | Produces chlorophenols (“swimming pool”) |

Bottom line: ClO₂ consistently achieves 3–6 log reductions of bacteria and viruses even in turbid water, and retains power at alkaline pH where bleach falters.

4. By-Products & Safety

- ClO₂ → chlorite, chlorate (non-carcinogenic; EPA MCL 1.0 mg/L).

- Bleach → trihalomethanes (THMs), halo acetic acids (HAAs), chloramines—regulated DBPs linked to bladder cancer risk.

Peer-reviewed studies show THM levels 14–30× higher with chlorine than with ClO₂ at equal microbial kill.

5. Operational & Environmental Factors

| Factor | ClO₂ Advantage | Bleach Limitation |

|---|---|---|

| Corrosivity | Mild; minimal impact on metals | Aggressive; escalates pipe degradation |

| pH Sensitivity | Stable 4–10 | Efficacy plunges >7.5 |

| Storage | Generated on demand (no long decay curve) | Shelf-life shortens with heat & light |

| Residual Control | Predictable ppm dosing | Unstable residuals in ammonia/organics |

| Environmental | Breaks to chlorite/chlorate | Chlorinated organics persist |

6. Providers & Technology Landscape

Scotmas (UK/Global) – modular ClO₂ generators for municipal, food, and cooling towers.

FILTEC – advanced disinfection skids for drinking, process, and wastewater.

Purita Water (TERSUS®) – compact 3 g/h–120 kg/h units, plug-and-play.

International Dioxcide (Anthium™) – NSF-certified chemistries for municipal & industrial.

Nalco Water (PURATE™) – onsite ClO₂ from sodium chlorate + peroxide; tight process control.

ProMinent (Bello Zon) – healthcare & hotel Legionella programs.

Dioxide Pacific, ZI-CHEM, SVS Aqua – niche and engineered systems for industrial, food, and agriculture.

Industrial-scale ClO₂ systems cost $25k–$250k depending on flow (g/h capacity), but pay back via lower chemical consumption, less corrosion, and DBP compliance.

7. Residential Perspective

Dedicated home ClO₂ generators are rare today. Small kits (~$30) sanitize cisterns, RVs, or odor issues but do not provide continuous metered residuals. Industrial “mini” generators exist ($2k–$6k) yet lack NSF/UL consumer approvals. Expect compact, smart-metered ClO₂ systems to reach residential wells within the next 3–5 years as regulators formalize standards.

8. Case Applications

- Municipal – distribution network DBP compliance, nitrification control.

- Cooling Towers – biofilm & Legionella prevention without pH swings.

- Food & Beverage – produce wash, CIP, and membrane protection.

- Industrial Wastewater – oxidizes phenols, cyanides, sulfides at low dose.

9. Quick Reference Table

| Feature | Chlorine Dioxide (ClO₂) | Sodium Hypochlorite |

|---|---|---|

| Microbial Efficacy | High, broad, cysticidal | Good, pH-limited |

| DBP Formation | Minimal | High THMs/HAAs |

| Biofilm Control | Excellent (penetrates) | Poor (surface only) |

| Corrosivity | Low | Higher |

| Residual Stability | Predictable | Unstable in organics |

| Infrastructure | Gentle | Accelerates decay |

| Environmental Risk | Low | Higher, persistent |

10. Conclusion

When weighed scientifically, chlorine dioxide outperforms bleach in log kill, DBP avoidance, biofilm penetration, and long-term asset protection. Bleach still “works,” but its chemical baggage makes compliance harder and infrastructure costlier. Forward-leaning utilities, processors, and building engineers are pivoting to ClO₂ for regulatory confidence and cleaner chemistry.

11. Next Steps

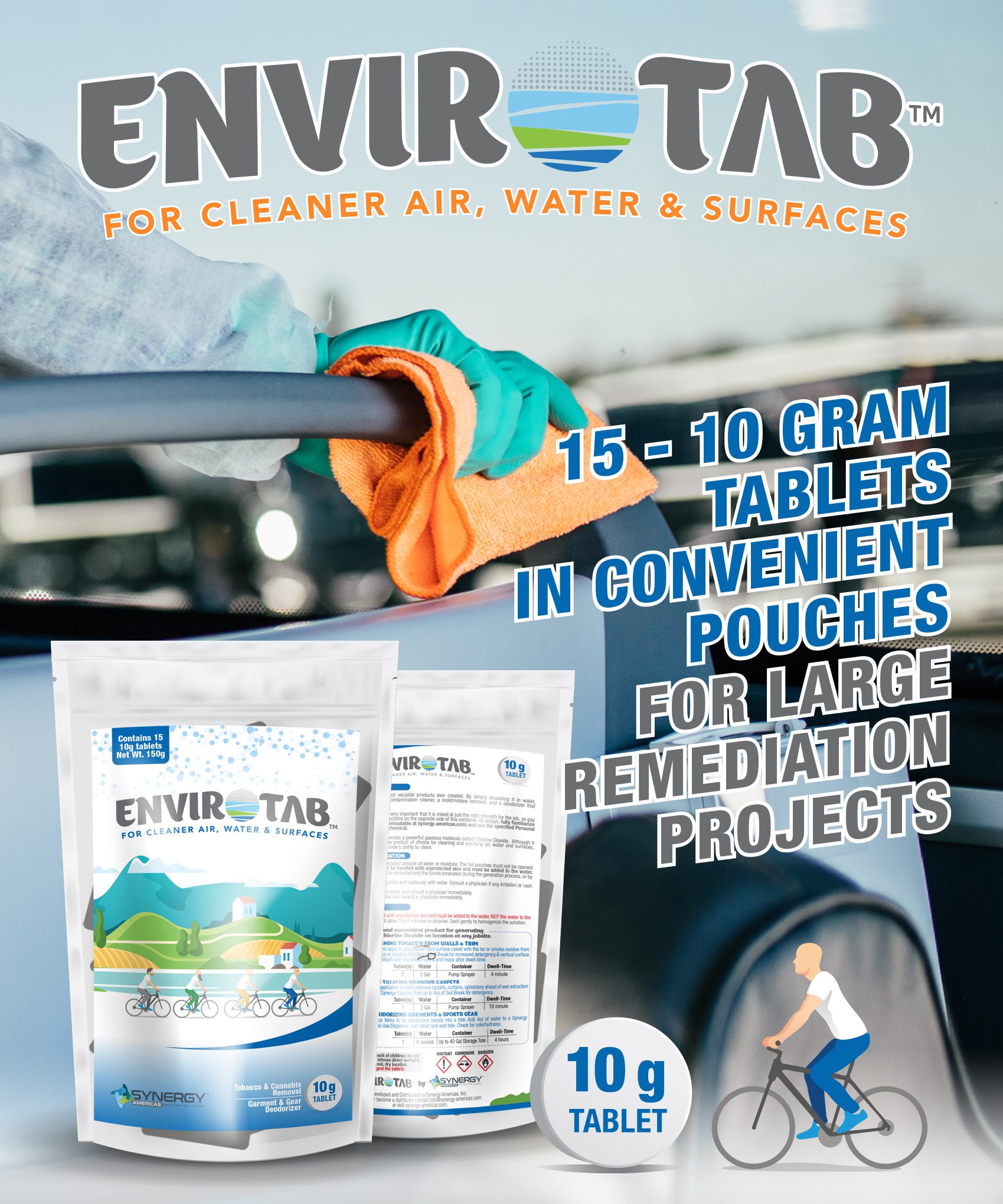

Pilot, don’t ponder. Contact Envirotab and Synergy Green Clean, to model ClO₂ dosing on your site. From Legionella mitigation to DBP-free municipal compliance, we’ll discuss the right move forward.