Revolutionizing Food Industry Sanitation: Why Chlorine Dioxide Is the Safer, Smarter Choice for Breweries, Food Plants, and Restaurants

Across the food industry, from high-capacity production plants to single-location restaurants, sanitation isn’t just about meeting compliance. It’s about safeguarding public health, preserving product integrity, and protecting your brand’s reputation. But traditional solutions like bleach and quaternary ammonium compounds (quats) come with significant downsides—corrosiveness, harsh odors, and chemical byproducts.

Today’s leaders in food safety are switching to chlorine dioxide (ClO₂)—a powerful, selective oxidizer that offers broad-spectrum disinfection with minimal risk, higher efficiency, and full EPA and FDA compliance.

Why Chlorine Dioxide Is Outperforming Traditional Disinfectants

ClO₂ eliminates a wide range of pathogens—including E. coli, Listeria, Salmonella, fungi, and viruses—even in the presence of organic matter, where bleach often fails. According to PureLine, ClO₂ is effective at low concentrations, leaves no harmful residues, and doesn’t produce toxic byproducts like trihalomethanes (THMs) or haloacetic acids (HAAs).

Additional advantages:

-

Non-corrosive: Preserves the lifespan of equipment

-

Versatile: Used for water treatment, surface disinfection, air purification, and produce sanitation

-

Biofilm penetration: ClO₂ gas breaks down microbial colonies that resist standard cleaners

-

Residue-free: Breaks down into non-toxic byproducts

How the Restaurant Industry Is Using ClO₂

How the Restaurant Industry Is Using ClO₂

Restaurants and commercial kitchens rely on ClO₂ for:

-

Surface disinfection: Cutting boards, food-contact surfaces, conveyors, drains, ceilings

-

Water treatment: Ensuring safe rinse water and cleaning systems

-

Air purification: Reducing airborne pathogens in prep areas

-

Produce sanitation: Washing raw fruits and vegetables

-

Odor control: Neutralizes persistent smells without fragrances

ClO₂ delivers safety without sacrificing effectiveness—an ideal balance for health inspections and high-volume service.

Also Read: How Can I Eliminate Odors & Bacteria from My Cutting Board?

ClO₂ in Breweries and Vintner Operations

Brewery managers face unique challenges: biofilms in tanks, wild yeast contamination, and the need to sanitize without affecting taste profiles. As shared on Synergy-Americas, ClO₂ solves these problems by offering:

-

Non-tainting sanitization

-

Final rinse or leave-in options

-

Lower water and energy usage

-

No rinse cycles required

Brewers are reporting faster turnaround times, less tank downtime, and higher product consistency with ClO₂.

Compliance, Safety, and Where to Get Started

ClO₂ must be used within regulatory guidelines. When applied correctly:

-

It complies with FDA and EPA regulations

-

Safe for food-contact surfaces and human exposure (when ventilated)

-

Requires basic PPE and standard safe handling practices

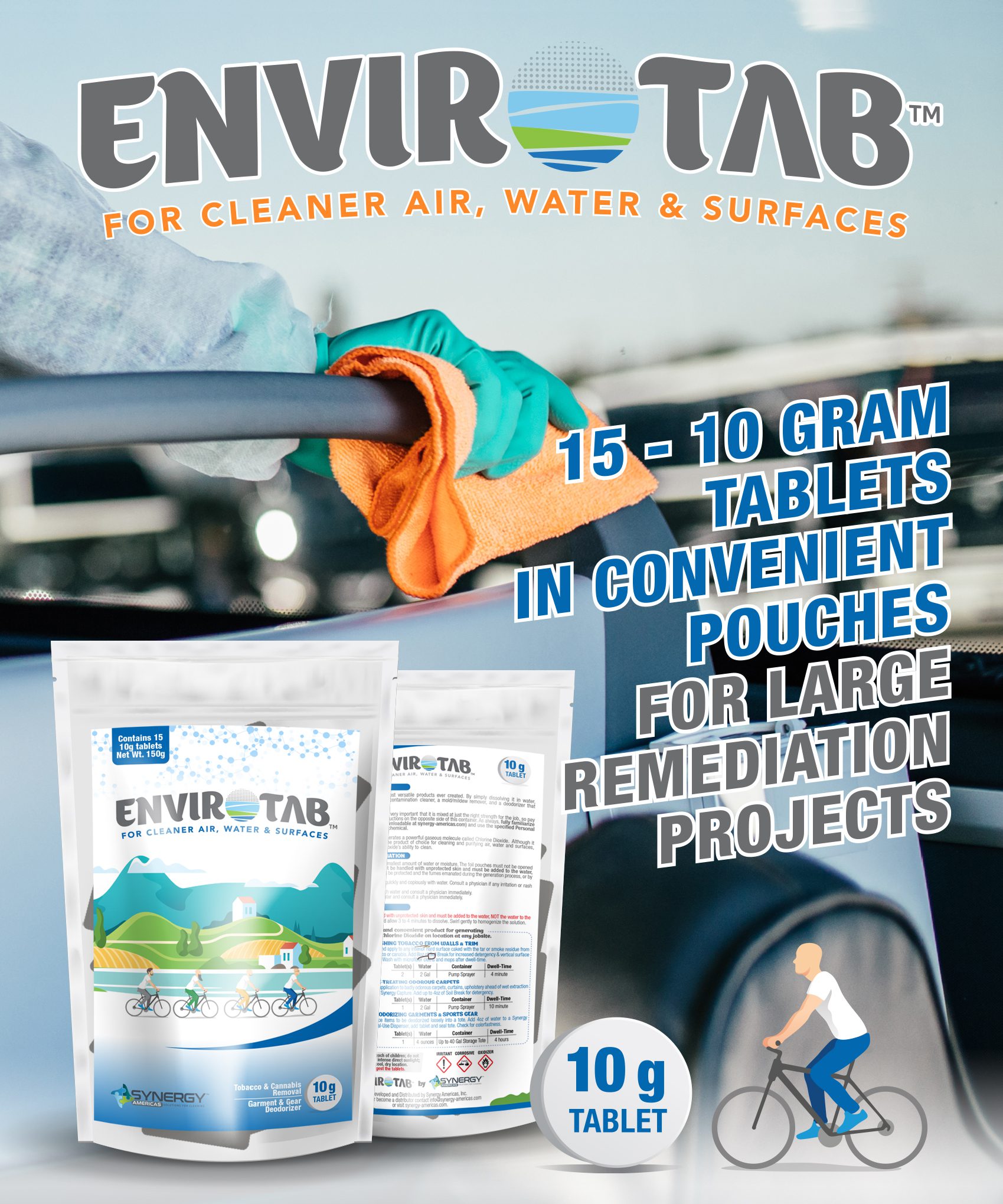

Interested businesses can purchase professional-grade ClO₂ tablets and systems at:

You can also connect with certified ClO₂ sanitation professionals through synergygreenclean.com, where decades of industry-specific experience is just a conversation away.

One-on-One Consultation: Let’s Build Your Plan

If you own or operate a restaurant, brewery, or food production facility and are considering switching to a safer, more advanced sanitation system, our commercial representatives are available to meet with you directly. We'll help you evaluate your current process, identify risks, and design a tailored ClO₂ program that meets your goals.

Cleaner environments. Safer products. Smarter sanitation.

Now is the time to elevate your cleaning program with chlorine dioxide.

Also Read: How Can CLO2 Tablets Improve Factory Cleaning Efficiency?