Redefining Food Safety with Smart Sanitation

The food industry is in constant motion — processing, packaging, transporting, and serving millions of meals every single day. With every step, the stakes are high: foodborne illnesses, spoilage, and contamination are risks that can cost lives and reputations. Enter chlorine dioxide tablets — the next-generation sanitation powerhouse that’s rewriting the rules of hygiene and safety across the global food sector.

Unlike traditional chlorine bleach or quaternary disinfectants, chlorine dioxide (ClO₂) offers targeted, residue-free, and highly effective sanitization. It neutralizes pathogens like Salmonella, E. coli, Listeria, and viruses — all while being gentle on surfaces, safe for food contact, and environmentally friendly.

In this comprehensive guide, we’ll explore how ClO₂ tablets are transforming food safety, prolonging shelf life, enhancing compliance, and protecting public health from farm to fork.

1. Pathogen Control with Chlorine Dioxide Tablets

Foodborne pathogens are microscopic invaders that can cause serious illness and massive recalls. From Listeria monocytogenes in ready-to-eat foods to E. coli in fresh produce, contamination risks are everywhere.

Chlorine dioxide tablets deliver a clean, simple solution. When dissolved in water, they release a precise dose of ClO₂ gas — a broad-spectrum oxidizing agent that destroys bacteria, fungi, and viruses at the cellular level. It works by rupturing the microbial cell wall and disrupting metabolic processes, ensuring full disinfection without resistance buildup.

This powerful yet safe action makes ClO₂ ideal for:

-

Fresh produce washing

-

Poultry and seafood processing

-

Food contact surface sanitation

-

Beverage and ice machine disinfection

ClO₂ even targets biofilms, those slimy, invisible layers that bacteria form on processing equipment. Eliminating biofilms means eliminating hidden contamination threats that often go unnoticed.

2. Extending Shelf Life in Food Processing

Every day, tons of food are lost to spoilage — not because it wasn’t stored properly, but because microbes worked faster than we could. Chlorine dioxide tablets change that timeline.

By drastically reducing microbial load, ClO₂ helps keep produce fresher, meats safer, and packaged goods more stable during transit. It minimizes oxidation and bacterial degradation, extending product life without the need for artificial preservatives.

For example:

-

Fresh-cut fruit processors use ClO₂ rinses to prevent browning and extend freshness.

-

Meat packers apply ClO₂ solutions to eliminate spoilage bacteria before packaging.

-

Cold storage operators use ClO₂ gas treatments to keep stored apples, citrus, and berries mold-free.

This smart technology means fewer recalls, longer shelf life, and greater profit margins — all while reducing waste.

3. Residue-Free Disinfection for Food Safety

Traditional disinfectants often leave chemical residues that can alter taste, corrode equipment, and pose regulatory challenges. Chlorine dioxide doesn’t.

ClO₂ breaks down into chloride ions and water, leaving no harmful by-products or lingering taste. It’s recognized by regulatory bodies, including the FDA and EPA, as a safe and effective sanitizer for food and beverage contact surfaces.

In practice, this means your sanitation process doesn’t compromise flavor, fragrance, or compliance. Consumers get food that’s safe and natural-tasting — a major trust factor in today’s clean-label market.

4. Improving Standards with ClO₂’s Consistent Performance

Food safety isn’t just about cleaning; it’s about consistency. Chlorine dioxide provides that reliability.

When you use ClO₂ tablets in your daily sanitation routine, you achieve measurable results every time — whether it’s a fruit rinse, floor sanitation, or clean-in-place (CIP) system. It ensures microbial kill rates remain above 99.9%, helping companies meet HACCP, FDA, and USDA standards effortlessly.

The uniform release and easy-to-measure dose of tablet-based ClO₂ eliminate guesswork, ensuring that safety protocols are repeatable and audit-friendly.

5. Preserving Taste and Odor Naturally

Unlike bleach or quaternary sanitizers that can leave chemical smells, ClO₂ neutralizes odors at the molecular level without covering them up. It eliminates volatile organic compounds (VOCs) and sulfur compounds responsible for spoilage odors.

The result? Fruits, vegetables, and packaged foods maintain their natural aroma and fresh taste. This is why many beverage companies and produce processors prefer ClO₂ — it safeguards both quality and sensory experience.

6. Versatile Applications in the Food Industry

6. Versatile Applications in the Food Industry

The versatility of chlorine dioxide tablets makes them indispensable in multiple food environments.

They can be used for:

-

Produce washing and storage sanitation

-

Meat, poultry, and seafood processing

-

Bakery, dairy, and beverage production

-

Equipment, conveyor, and container disinfection

-

Water purification and CIP systems

-

Air and surface sanitation in cold storage facilities

Beyond food, ClO₂ tablets are widely used in hospitals, farms, and hospitality settings, showcasing their broad disinfection potential.

7. Cost-Effective Sanitization that Saves Time and Money

Efficiency meets economy with ClO₂. The tablets dissolve quickly, produce controlled-release ClO₂ gas, and deliver superior microbial kill rates using less product than most traditional sanitizers.

Benefits include:

-

Lower labor costs (no complicated mixing or dosing systems)

-

Reduced chemical waste

-

Less equipment corrosion

-

Longer operational uptime

-

Compact storage and low shipping weight

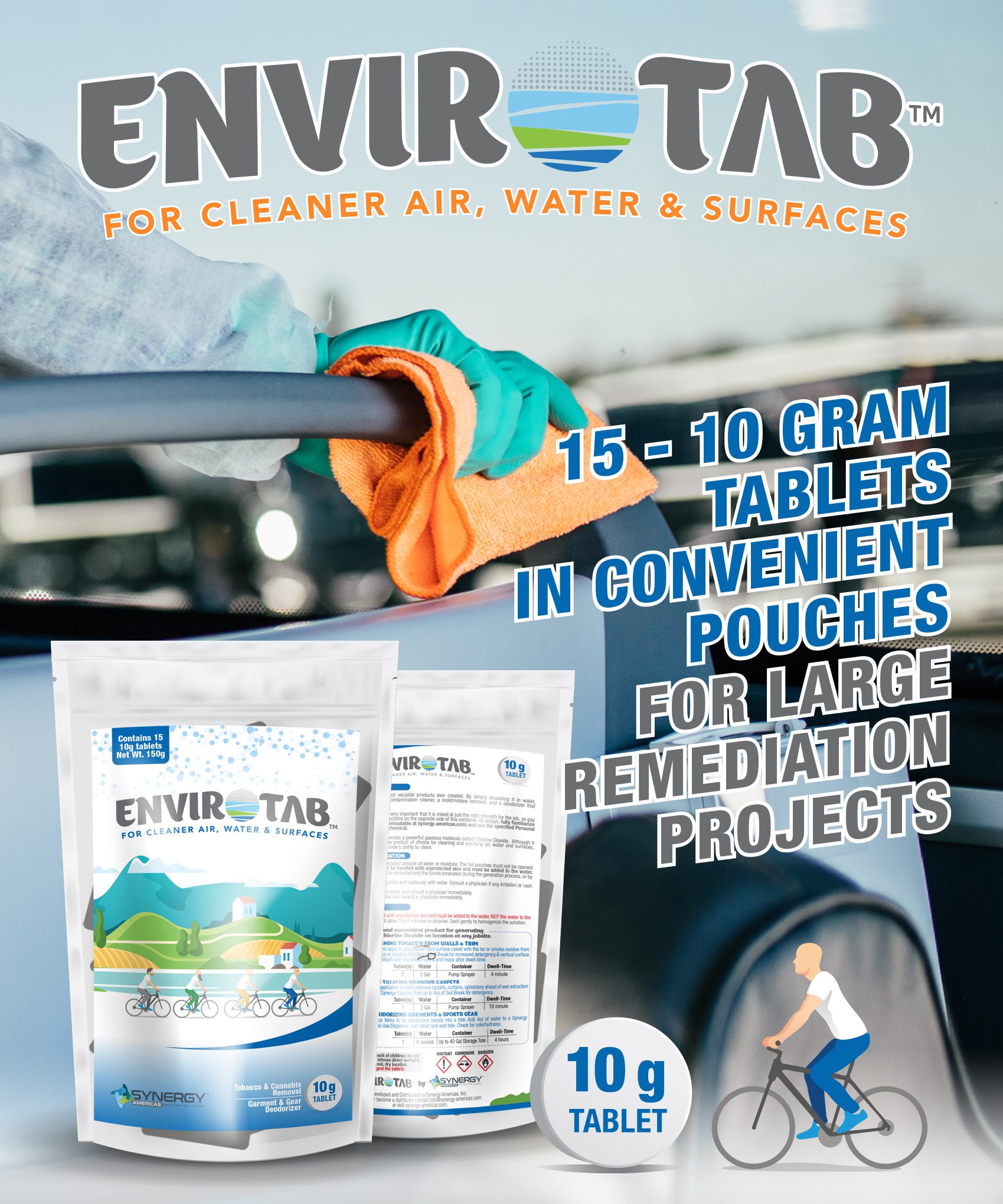

ClO₂ tablets like Envirotab for Surfaces and Envirotab for Odor Elimination deliver industrial performance at an affordable cost — making them ideal for farms, processing plants, restaurants, and catering facilities.

8. Ensuring Regulatory Compliance with Ease

In today’s food sector, compliance is the golden rule. From HACCP and FSMA to ISO and FDA guidelines, facilities must demonstrate safe handling and documentation of every sanitation step.

Chlorine dioxide simplifies that process. Because it’s already recognized as a safe and approved sanitizer, facilities using ClO₂ align naturally with global standards. The residue-free profile also makes export and certification processes smoother, eliminating delays due to residual testing.

By adopting ClO₂, companies not only stay compliant — they elevate their credibility in the marketplace.

9. Boosting Food Quality Through Science and Safety

At its core, chlorine dioxide is not just a sanitizer — it’s a quality assurance tool. It ensures that food remains microbiologically safe, visually appealing, and organoleptically consistent.

The science is clear: ClO₂ effectively inactivates microbial contaminants while maintaining texture, flavor, and color integrity. This makes it a preferred sanitization solution for brands that value both safety and sensory quality.

When consumers see “processed using chlorine dioxide sanitation,” it communicates advanced care, cleanliness, and transparency — three traits that define modern food brands.

10. Supporting Sustainable and Eco-Friendly Operations

ClO₂ is part of a greener sanitation future.

-

It reduces chemical waste and water consumption.

-

It biodegrades safely into natural ions.

-

It replaces harsh, corrosive sanitizers with a cleaner chemistry.

For companies pursuing ESG goals, sustainability certifications, or carbon footprint reduction, chlorine dioxide offers measurable progress toward eco-friendly manufacturing.

Conclusion: The Smart Future of Food Safety

The food industry’s success depends on trust — and trust begins with safety.

Chlorine dioxide tablets have emerged as the modern answer to an age-old challenge: how to keep food safe, fresh, and compliant without sacrificing quality or sustainability.

Whether you’re a grower, packer, processor, or distributor, integrating ClO₂ into your sanitation program can deliver cleaner food, longer shelf life, and stronger brand confidence.

👉 Learn more or order your supply today at clo2tablets.com — where science meets sustainability in food protection.

6. Versatile Applications in the Food Industry

6. Versatile Applications in the Food Industry